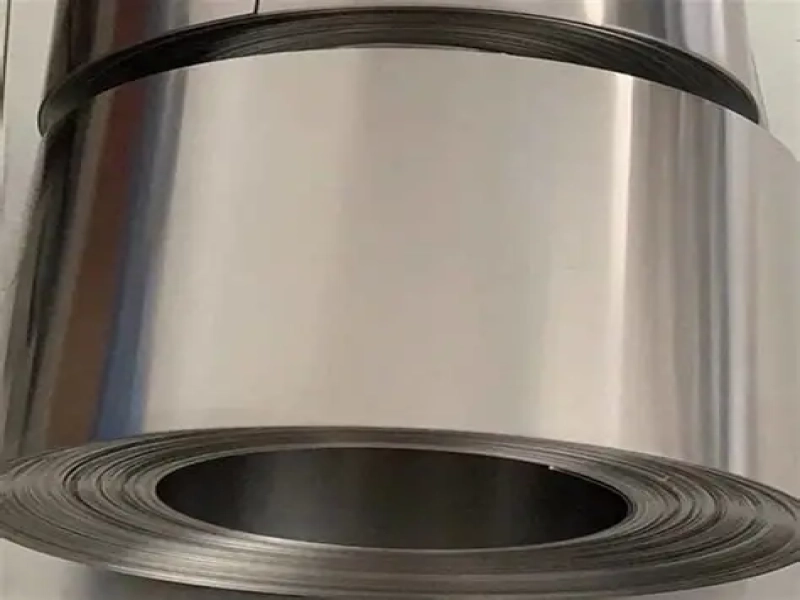

Hot-rolled silicon steel sheet

Customized one-stop solution for transformers

It complies with standards like GB/T 5212 and IEC 60404, and features relatively simple production process and low cost.

Product Introduction

Hot-rolled silicon steel sheet is a type of electrical steel produced by hot rolling process, with a silicon content usually ranging from 0.5% to 4.5%. The addition of silicon can improve the magnetic properties of the material. It is suitable for manufacturing iron cores of electromagnetic equipment with low-frequency and low-performance requirements, such as small motors, transformers, inductors, etc. It complies with standards like GB/T 5212 and IEC 60404, and features relatively simple production process and low cost.

Product Features

It has lower permeability and higher core loss than cold-rolled silicon steel sheets but meets basic needs at 50Hz-60Hz. With coarser grains, irregular crystal orientation, and uneven magnetic properties, it features lower costs due to simpler production and higher material utilization. Though plastic enough for shearing/stamping, its poorer surface quality reduces processing accuracy versus cold-rolled products. Limited by magnetic performance, it’s unsuitable for high-frequency/high-performance equipment like large transformers and precision motors.

Product Classification

- By silicon content:Low-silicon steel sheet (silicon content 0.5%-1.0%, low magnetic permeability, high core loss, suitable for occasions with low performance requirements); medium-silicon steel sheet (silicon content 1.0%-3.0%, moderate magnetic performance, with a wide range of applications); high-silicon steel sheet (silicon content 3.0%-4.5%, improved magnetic permeability, relatively reduced core loss, suitable for equipment with certain requirements on magnetic performance).

- By thickness:Thick gauge (0.5mm-1.0mm, good rigidity, suitable for large simple core structures); thin gauge (0.35mm-0.5mm, slightly better flexibility, can be used in small motors and other equipment).

- By surface state:Uncoated hot-rolled silicon steel sheet (no special treatment on the surface, needs rust prevention treatment before use); painted hot-rolled silicon steel sheet (surface coated with insulating paint, which can enhance insulation performance and rust resistance).

After-sales Service

It features strict quality control with each batch undergoing magnetic performance testing (core loss, permeability, etc.), dimensional accuracy and surface quality inspections, accompanied by quality reports to support customer re-inspection; offers technical support including product selection advice, recommending products with suitable silicon content and thickness based on customers' equipment performance needs, and providing processing technology guidance; and ensures supply with regular specifications shipped within 72 hours, special specifications customizable with a 15-20 day delivery cycle, and bulk purchase support.