220kV Oil-immersed Power Transformers

Customized one-stop solution for transformers

The 220kV oil-immersed power transformer is a core equipment of the high-voltage power transmission

network, focusing on the main transformer scenarios of 220kV substations. Using mineral oil as the insulation

and cooling medium, it features efficient heat dissipation and stable operation performance, and is widely used

in substations, power plants and industrial power distribution systems. The production strictly complies with

standards such as IEC 60076 and GB 1094. An intelligent monitoring system can be optionally configured as

needed to collect data such as temperature, oil level and load in real time, proactively warn of potential faults,

help operation and maintenance personnel to carry out maintenance in a timely manner, reduce the risk of

sudden power outages, and thus significantly improve the safety and operation resilience of the power grid.

Compared with 110kV products, it has a higher voltage level, is adapted to ultra-high voltage power

transmission, and the intelligent monitoring focuses on the global-level fault prevention of the power grid.

Product Introduction

The 220kV oil-immersed Power Transformer is a core equipment in the high-voltage transmission network, focusing on the main transformer scenario of 220kV substations. Using mineral oil as the insulation and cooling medium, it has efficient heat dissipation and stable operation performance, and is widely used in substations, power plants and industrial distribution systems. Its production strictly complies with standards such as IEC 60076 and GB 1094. It can be optionally equipped with an intelligent monitoring system to collect real-time data such as temperature, oil level and load, actively warn of potential faults, help operation and maintenance personnel carry out maintenance work in a timely manner, reduce the risk of sudden power outages, and thus significantly improve the safety and operational resilience of the power grid. Compared with 110kV products, it has a higher voltage level, is suitable for the ultra-high voltage main transmission network, and its intelligent monitoring focuses on global-level fault prevention of the power grid.

Product Features

Adopting high-quality cold-rolled silicon steel core, fully inclined non porous structure combined with low magnetic steel plate pull plate, forming a stable steel body, reducing no-load loss and noise; The winding structure is diverse, combined with transposed wires and computer simulation optimization, to improve electrical characteristics and impact resistance strength; The fuel tank has a flat top design, with reinforced iron walls to enhance mechanical strength and magnetic shielding to reduce stray losses; The positioning device prevents transportation displacement, and the sealed oil storage tank and pointer type oil level gauge ensure stable oil quality; It has excellent impact resistance, short-circuit resistance, low partial discharge, low loss, good sealing performance, and is suitable for key scenarios such as power plants and substations.

Product Classification

Classified by phase number:

Three phase transformer and single-phase transformer

Double winding transformer and three winding transformer

Classified by cooling method:

Oil immersed self cooling, oil immersed air-cooled, forced oil circulation air-cooled, forced oil circulation water-cooled

Classified by voltage regulation method:

Non excited voltage regulating transformer and on load voltage regulating transformer

Classified by structural form:

Iron core transformer and iron shell transformer

After-sales Service

The after-sales service system for 220kV oil immersed power transformers is complete and efficient. We provide a 24-hour service hotline around the clock, which can quickly respond to fault reports and ensure that technical personnel arrive at the scene within the specified time. The service content covers fault diagnosis, emergency repair, preventive testing, and regular inspections, using professional equipment to accurately detect key indicators such as insulation and oil quality, and eliminate hidden dangers in advance. At the same time, establish a vulnerable parts and spare parts warehouse to ensure rapid replacement. We also provide technical training and operational guidance for users to enhance their independent operation and maintenance capabilities. Free maintenance is provided during the warranty period, and lifetime maintenance is offered outside of the warranty period. Only reasonable cost fees are charged to ensure the long-term stable operation of the transformer with professional and thoughtful service.

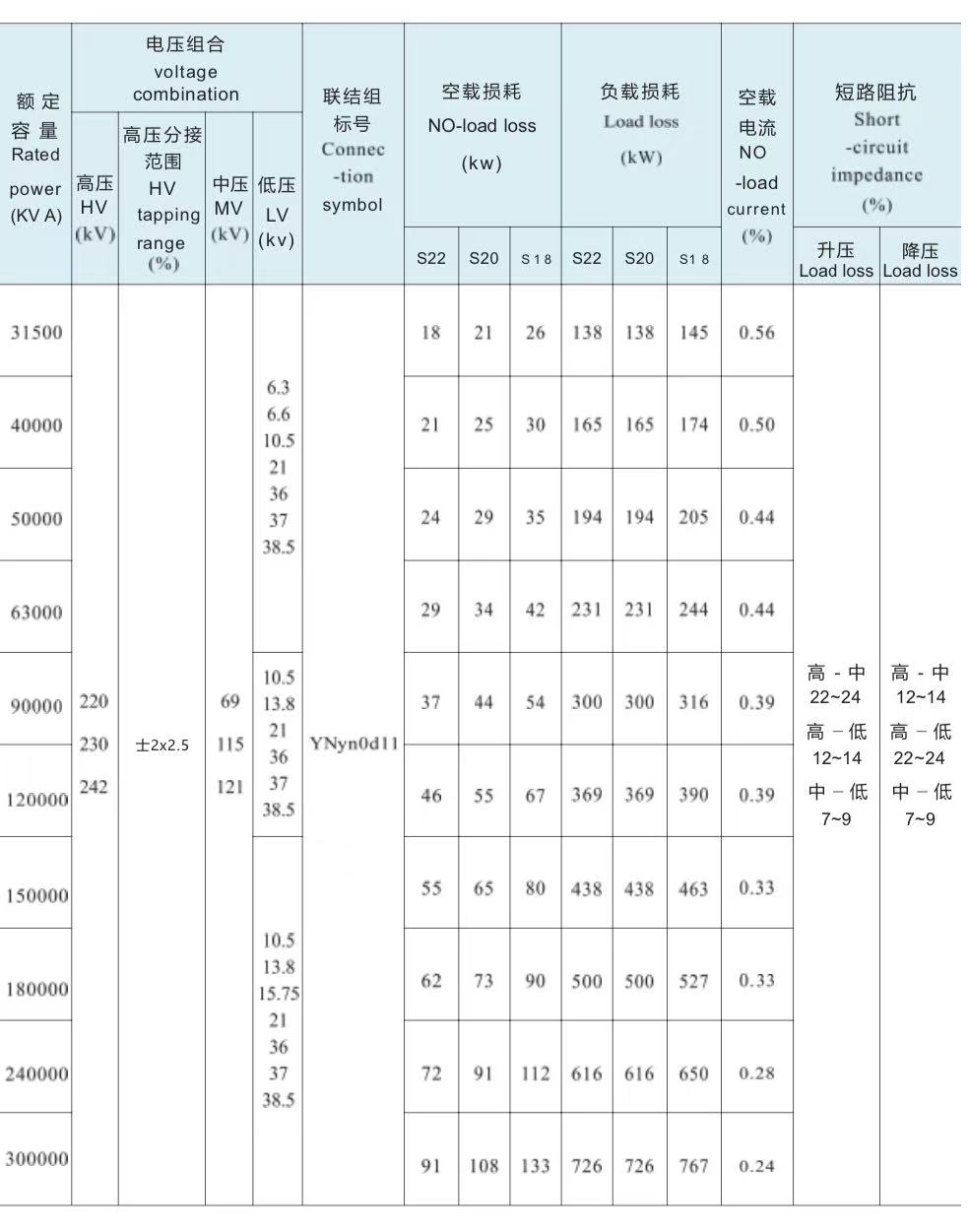

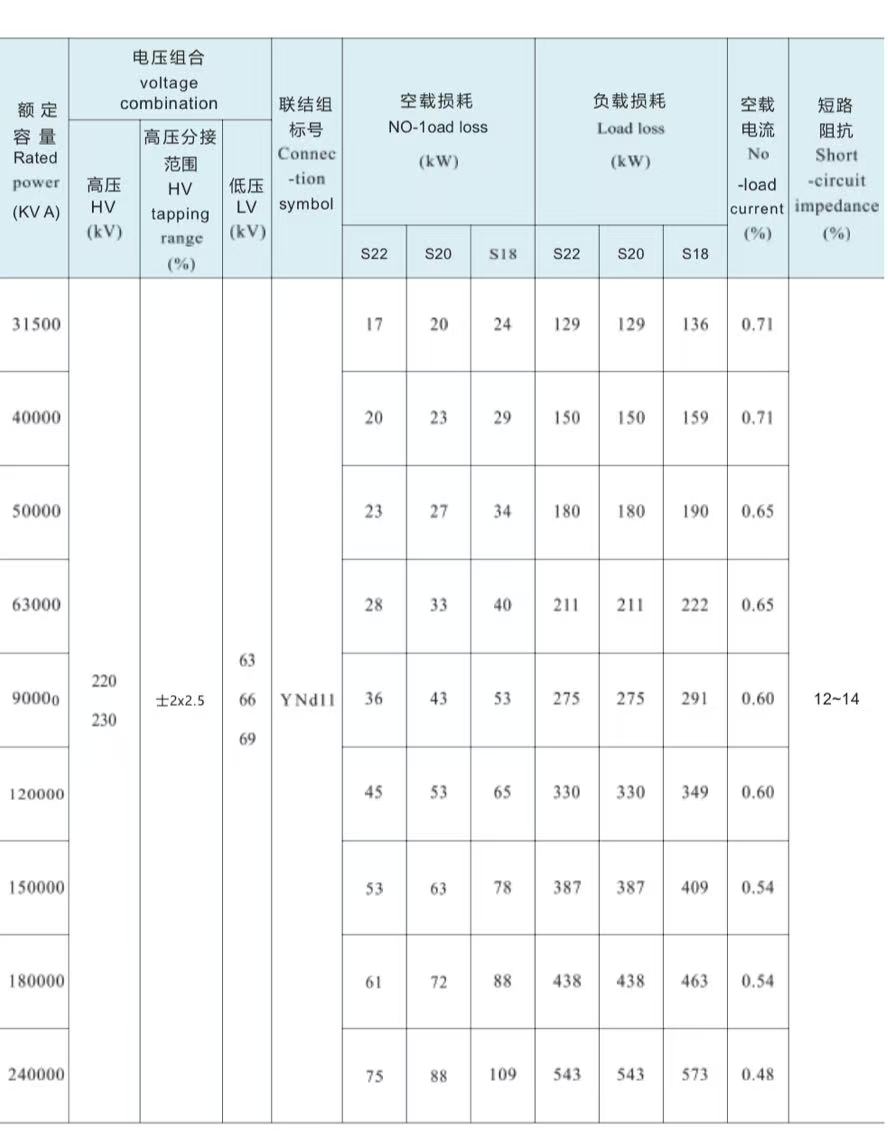

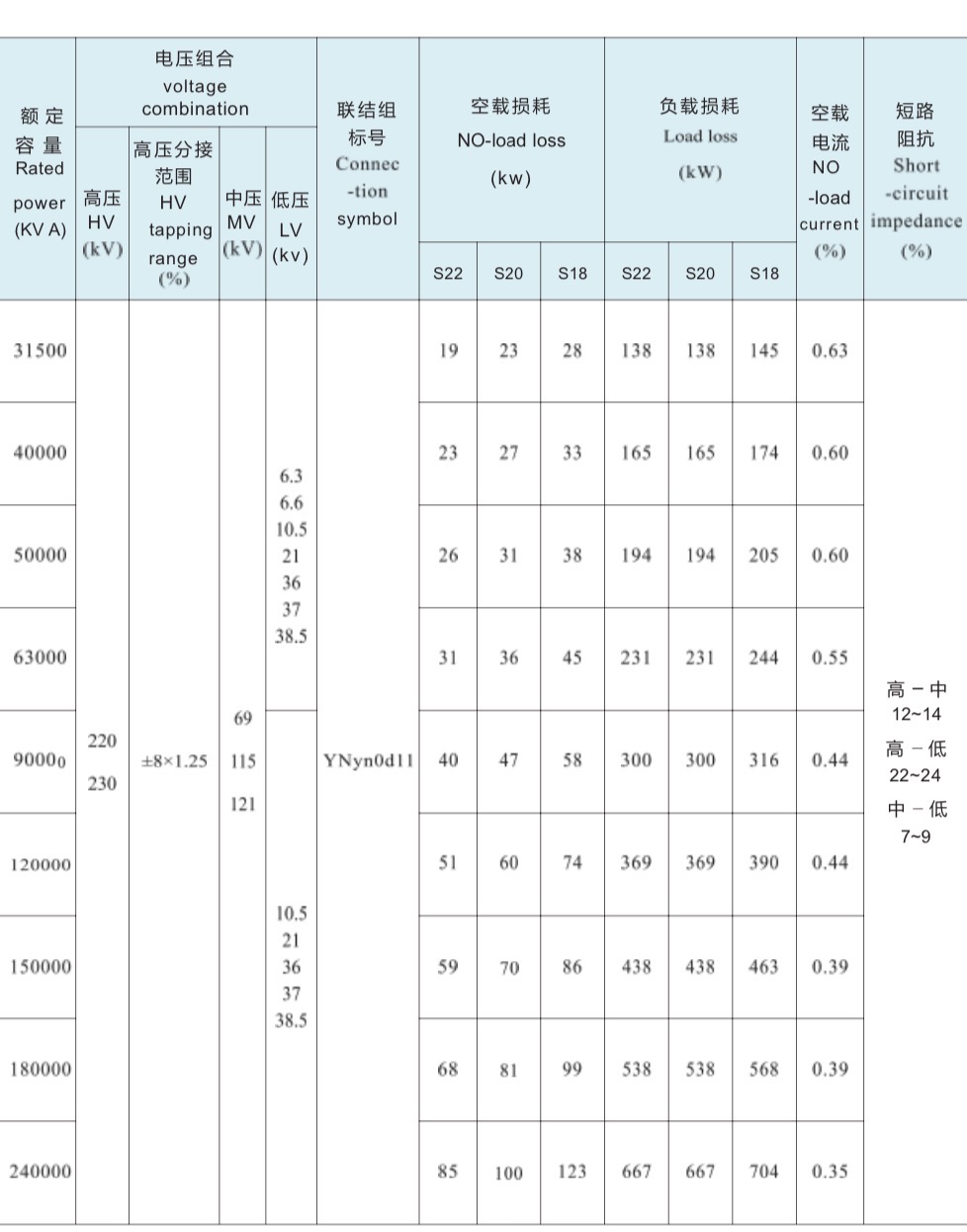

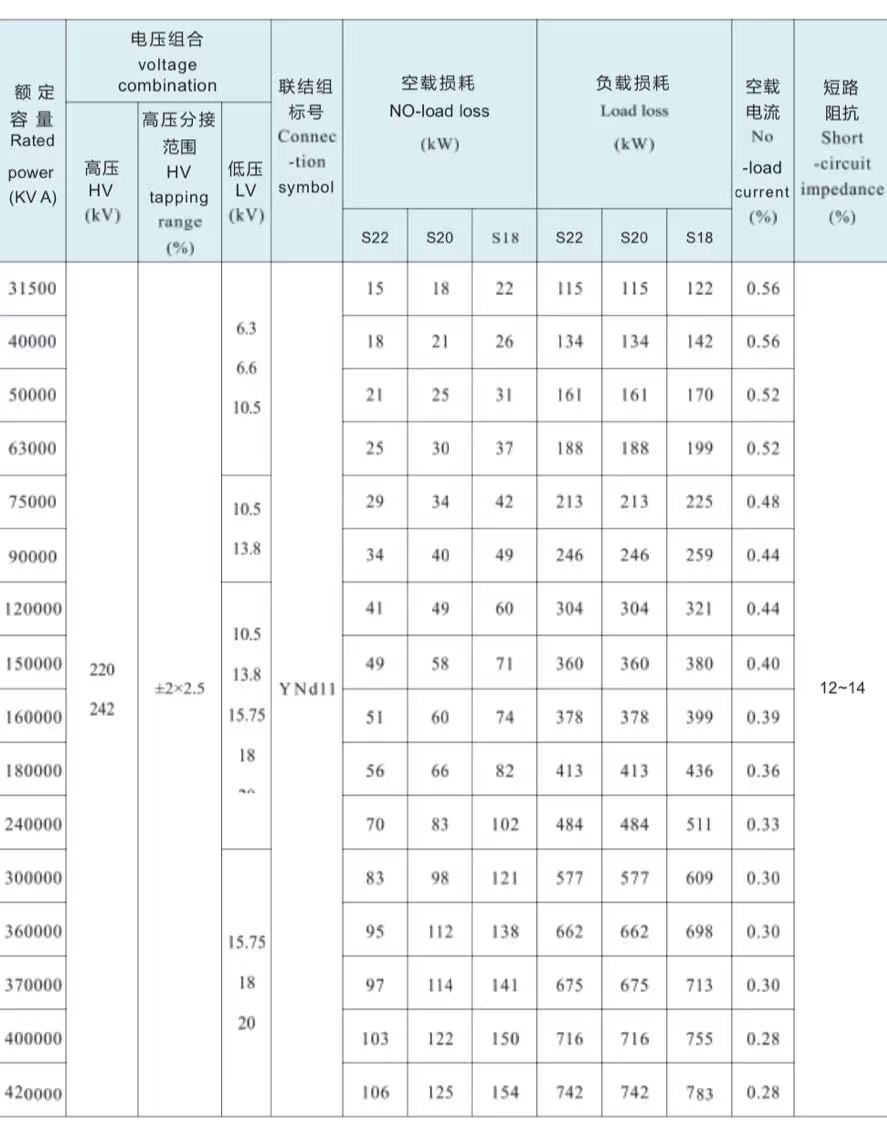

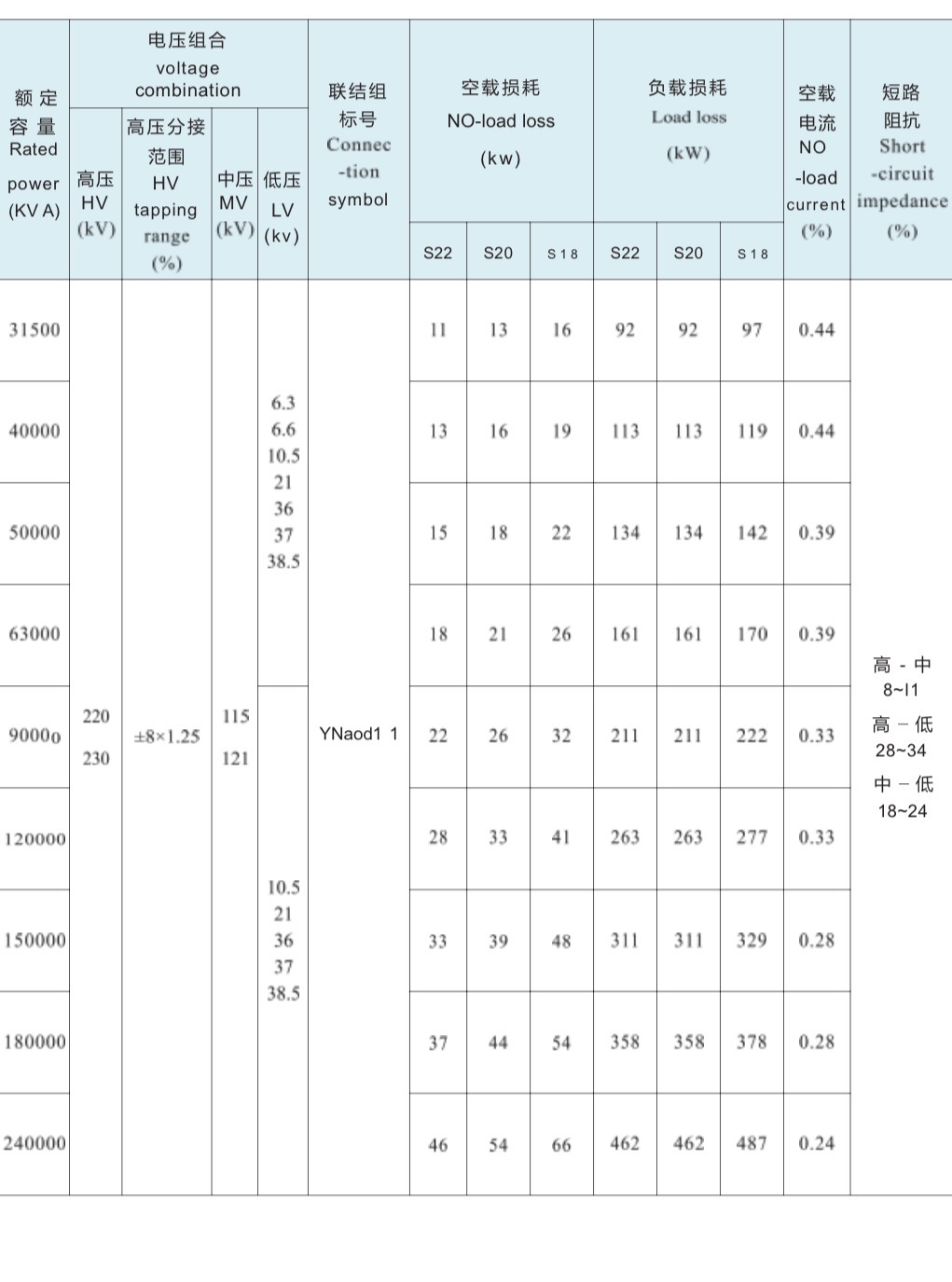

Technical Parameters